Wed, 26 Feb 2025 14:49:48 +0100

Ultrasonic cleaning is a process that uses high-frequency sound waves to remove contaminants from the surfaces of objects immersed in a liquid. These waves generate a phenomenon known as cavitation, where microbubbles form and collapse in the liquid, producing an intense cleaning action that reaches even the most inaccessible areas of the parts. This method is especially useful for components with complex geometries, such as cardans.

Cardan shafts are key elements in the transmission of motion and power between different parts of a machine or vehicle. Their correct operation is vital for the efficiency and safety of the system in which they are integrated. The accumulation of contaminants such as dust, grease, oil and metal residue can cause:

Therefore, regular and effective cleaning is essential to maintain the functionality and prolong the life of cardan shafts.

DISCOVER OUR MACHINE FOR CLEANING CARDANS

1. Efficiency in Removing Contaminants:

The cavitation generated by ultrasound allows for the effective removal of oils, grease, oxides and other residues adhering to the surface of the cardan shaft.

2. Access to Hard-to-Reach Areas:

Microbubbles reach internal cavities, grooves and complex areas where other cleaning methods cannot reach.

3. Non-Abrasive Process:

Unlike mechanical methods, ultrasonic cleaning does not wear down or damage the surfaces of the cardan shaft, preserving its tolerances and finishes.

4. Reduction in Cleaning Time:

This method is significantly faster than traditional techniques, optimizing maintenance times and reducing downtime.

5. Resource Savings:

It reduces the need for aggressive chemicals and reduces water consumption, contributing to more sustainable and economical practices.

6. Improved Workplace Safety:

By minimizing the use of hazardous solvents and eliminating the need for intensive manual handling, the associated risks for operators are reduced.

Ultrasonic cleaning of cardan shafts offers multiple benefits compared to traditional methods. The main advantages are highlighted below:

1. Efficient Removal of Contaminants

Ultrasound generates a cavitation effect that breaks down and loosens dirt embedded in the cardan shafts, effectively removing oils, grease, oxides, carbon and other residues without the need to scrub or use harsh chemicals.

2. Access to Hard-to-Reach Areas

Given the structural design of cardan shafts, many internal areas may be inaccessible with manual or mechanical cleaning methods. Ultrasound allows for deep cleaning in slots, holes and cavities without disassembling the component, ensuring complete sanitation.

3. Reduced Cleaning Time

Unlike traditional methods, ultrasonic cleaning is significantly faster, reducing maintenance times and avoiding long periods of machine downtime. This improves productivity in industrial and automotive sectors.

4. Non-Abrasive and Safe Process for Components

Unlike sandblasting or metal brushes, which can damage the surface of the cardan shafts, ultrasonic cleaning is a non-abrasive process that preserves the structural integrity of the component without altering its tolerances or surface finishes.

SEE CARDAN CLEANING MACHINE - UCM 1000DL LONG

5. Energy Efficiency and Reduction in the Use of Chemicals

Ultrasonic cleaning systems require less energy and less chemical solvents compared to other methods, which reduces environmental impact and operating costs, aligning with sustainable maintenance practices.

6. Improved Cardan Performance and Durability

By efficiently removing residue and contaminants, premature wear of the cardan shafts is minimized, optimizing their operation and prolonging their useful life. This prevents costly breakdowns and reduces the need for frequent replacements.

7. Application in Various Industrial Sectors

Ultrasonic cleaning of cardan shafts is a versatile solution used in sectors such as the automotive, railway, aeronautical and heavy machinery industries, where power transmission is crucial for the performance of the equipment.

8. Effective Preventive Maintenance

Periodic ultrasonic cleaning allows the detection of hidden problems in the cardan shafts, such as cracks or excessive wear, facilitating timely preventive maintenance that avoids unexpected failures.

9. Adaptability to Different Types and Sizes of Cardan Shafts

Ultrasonic systems can be configured to clean cardan shafts of various sizes and geometries, from small transmission shafts to large industrial machinery cardan shafts.

10. Optimizing Compliance with Quality Standards

Ultrasonic cleaning ensures an optimal level of cleanliness, helping companies meet strict quality and safety standards in sectors where the reliability of mechanical components is critical.

Ultrasonic cleaning has become the best solution for efficient maintenance of gimbals, guaranteeing optimal performance, reducing wear and ensuring deep cleaning without compromising the integrity of the parts. Compared to other traditional methods, ultrasound offers faster, safer and more sustainable cleaning, becoming the preferred choice for industrial sectors where gimbal reliability is essential. DCM Ultrasonic, cleaning solutions for industry.

News

Cleaning of universal joints with ultrasonic bath

26 February de 2025

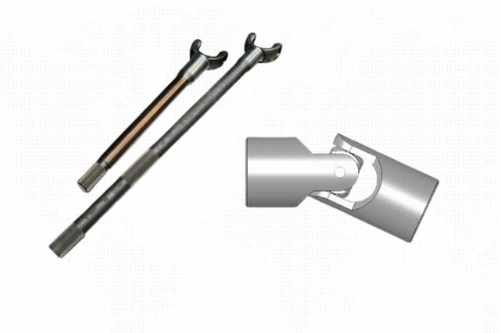

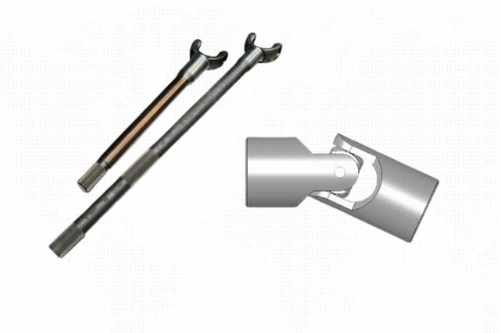

Cleaning mechanical components is essential to ensure their optimal performance and prolong their lifespan. Among these components, universal joints play a crucial role in power transmission in various industrial and automotive systems. Due to their design and function, universal joints are exposed to conditions that can accumulate dirt, grease and other contaminants that affect their performance. Ultrasonic cleaning is presented as an efficient and effective solution to keep these components in optimal condition.Ultrasonic cleaning is a process that uses high-frequency sound waves to remove contaminants from the surfaces of objects immersed in a liquid. These waves generate a phenomenon known as cavitation, where microbubbles form and collapse in the liquid, producing an intense cleaning action that reaches even the most inaccessible areas of the parts. This method is especially useful for components with complex geometries, such as cardans.

Importance of universal joint cleaning

Cardan shafts are key elements in the transmission of motion and power between different parts of a machine or vehicle. Their correct operation is vital for the efficiency and safety of the system in which they are integrated. The accumulation of contaminants such as dust, grease, oil and metal residue can cause:

- Premature Wear: The presence of abrasive particles accelerates the deterioration of contact surfaces.

- Corrosion: Contaminants can retain moisture, encouraging oxidation and corrosion of the metal.

- Imbalance: Uneven accumulation of dirt can cause imbalances, generating vibrations and possible mechanical failures.

- Loss of Efficiency: Additional friction due to contaminants reduces power transmission efficiency.

Therefore, regular and effective cleaning is essential to maintain the functionality and prolong the life of cardan shafts.

DISCOVER OUR MACHINE FOR CLEANING CARDANS

Benefits of Ultrasonic Cleaning in Cardan Shafts

1. Efficiency in Removing Contaminants:

The cavitation generated by ultrasound allows for the effective removal of oils, grease, oxides and other residues adhering to the surface of the cardan shaft.

2. Access to Hard-to-Reach Areas:

Microbubbles reach internal cavities, grooves and complex areas where other cleaning methods cannot reach.

3. Non-Abrasive Process:

Unlike mechanical methods, ultrasonic cleaning does not wear down or damage the surfaces of the cardan shaft, preserving its tolerances and finishes.

4. Reduction in Cleaning Time:

This method is significantly faster than traditional techniques, optimizing maintenance times and reducing downtime.

5. Resource Savings:

It reduces the need for aggressive chemicals and reduces water consumption, contributing to more sustainable and economical practices.

6. Improved Workplace Safety:

By minimizing the use of hazardous solvents and eliminating the need for intensive manual handling, the associated risks for operators are reduced.

Advantages of Ultrasonic Cleaning for Universal joints and cardans

Ultrasonic cleaning of cardan shafts offers multiple benefits compared to traditional methods. The main advantages are highlighted below:1. Efficient Removal of Contaminants

Ultrasound generates a cavitation effect that breaks down and loosens dirt embedded in the cardan shafts, effectively removing oils, grease, oxides, carbon and other residues without the need to scrub or use harsh chemicals.

2. Access to Hard-to-Reach Areas

Given the structural design of cardan shafts, many internal areas may be inaccessible with manual or mechanical cleaning methods. Ultrasound allows for deep cleaning in slots, holes and cavities without disassembling the component, ensuring complete sanitation.

3. Reduced Cleaning Time

Unlike traditional methods, ultrasonic cleaning is significantly faster, reducing maintenance times and avoiding long periods of machine downtime. This improves productivity in industrial and automotive sectors.

4. Non-Abrasive and Safe Process for Components

Unlike sandblasting or metal brushes, which can damage the surface of the cardan shafts, ultrasonic cleaning is a non-abrasive process that preserves the structural integrity of the component without altering its tolerances or surface finishes.

SEE CARDAN CLEANING MACHINE - UCM 1000DL LONG

5. Energy Efficiency and Reduction in the Use of Chemicals

Ultrasonic cleaning systems require less energy and less chemical solvents compared to other methods, which reduces environmental impact and operating costs, aligning with sustainable maintenance practices.

6. Improved Cardan Performance and Durability

By efficiently removing residue and contaminants, premature wear of the cardan shafts is minimized, optimizing their operation and prolonging their useful life. This prevents costly breakdowns and reduces the need for frequent replacements.

7. Application in Various Industrial Sectors

Ultrasonic cleaning of cardan shafts is a versatile solution used in sectors such as the automotive, railway, aeronautical and heavy machinery industries, where power transmission is crucial for the performance of the equipment.

8. Effective Preventive Maintenance

Periodic ultrasonic cleaning allows the detection of hidden problems in the cardan shafts, such as cracks or excessive wear, facilitating timely preventive maintenance that avoids unexpected failures.

9. Adaptability to Different Types and Sizes of Cardan Shafts

Ultrasonic systems can be configured to clean cardan shafts of various sizes and geometries, from small transmission shafts to large industrial machinery cardan shafts.

10. Optimizing Compliance with Quality Standards

Ultrasonic cleaning ensures an optimal level of cleanliness, helping companies meet strict quality and safety standards in sectors where the reliability of mechanical components is critical.

Ultrasonic cleaning has become the best solution for efficient maintenance of gimbals, guaranteeing optimal performance, reducing wear and ensuring deep cleaning without compromising the integrity of the parts. Compared to other traditional methods, ultrasound offers faster, safer and more sustainable cleaning, becoming the preferred choice for industrial sectors where gimbal reliability is essential. DCM Ultrasonic, cleaning solutions for industry.