Mon, 10 Feb 2025 16:59:31 +0100

Transducers can be installed in different ways depending on the needs of the cleaning process and the characteristics of the tank. The two most common options are submersible transducers and plate transducers.

Advantages of Submersible Transducers

1. Uniform distribution of ultrasonic waves

Thanks to their ability to be installed in different positions within the tank, submersible transducers allow for a better distribution of ultrasonic energy, minimizing dead zones and optimizing the cleaning process.

2. Flexibility and Scalability

Submersible transducers can be added or relocated depending on the needs of the cleaning process. This allows the tank configuration to be adapted without requiring costly structural modifications.

3. Ease of maintenance and replacement

Since they are not permanently fixed to the tank, their maintenance and replacement is much simpler. In the event of failure or wear, they can be replaced without affecting the integrity of the tank or interrupting the production process for long periods.

4. Longer service life

Since submersible transducers are designed with a hermetically sealed stainless steel housing, their service life tends to be longer compared to plate transducers, which are subject to greater wear from direct contact with cleaning fluids and the action of chemicals.

5. Suitable for large volume tanks

For industrial cleaning systems that require large capacity tanks, submersible transducers can be installed in multiple locations to ensure efficient distribution of ultrasonic energy.

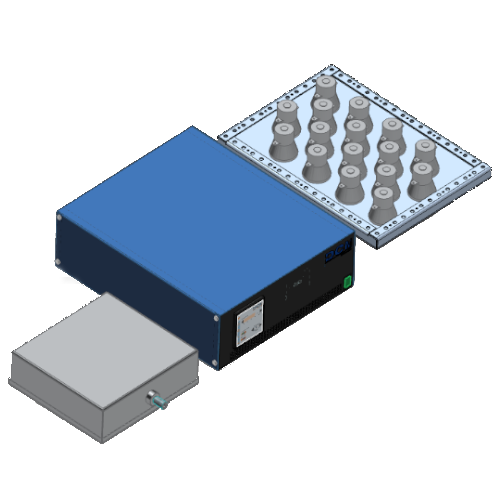

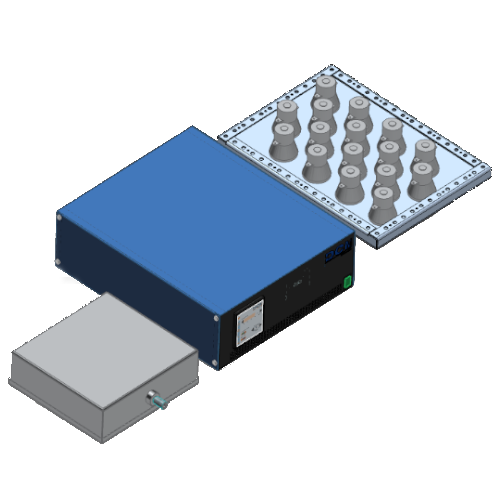

DCM ULTRASONIC GENERATORS AND EMITTERS

Plate transducers are integrated into the base or walls of the cleaning tank and are part of its structure. They are usually permanently installed and require a specific tank design for proper implementation.

Disadvantages of Plate Transducers

1. Less flexibility

Once installed, plate transducers cannot be easily relocated. If a change in ultrasound distribution is required, structural modifications to the tank are required, which means additional costs and production downtime.

2. More complex maintenance

In the event of failure or deterioration, repairing or replacing a plate transducer can be expensive and complex, as it involves intervening directly in the tank. This can translate into extended downtime and higher maintenance costs.

3. Increased wear and reduced service life

Because they are in direct contact with cleaning fluid and chemicals, plate transducers can suffer greater wear over time. In addition, residue build-up and corrosion can affect their performance.

4. Less efficient wave distribution

The fixed location of plate transducers can result in zones of lower ultrasonic intensity within the tank, which can compromise the effectiveness of the cleaning process, especially in configurations with complexly shaped parts.

5. Limitations in demanding industrial applications

For applications requiring high ultrasonic intensity or deep, uniform cleaning, plate transducers may not be the most suitable choice due to their limitations in distributing ultrasonic energy.

Comparison

The choice between submersible and plate transducers depends on a number of factors such as the type of application, tank size, required flexibility, and available budget. However, generally speaking, submersible transducers offer greater advantages in terms of efficiency, maintenance, flexibility, and service life, making them the preferred choice for most industrial applications.

Plate transducers may be suitable in cases where the tank structure is specifically designed for this type of installation and a more economical solution is prioritized in the initial phase. However, it is important to consider maintenance costs and long-term performance limitations before making a decision.

At DCM Ultrasonic, we offer advanced ultrasonic solutions with high-quality submersible transducers, designed to optimize cleaning processes in various industries. Our focus on innovation and efficiency ensures reliable equipment, with cutting-edge technology to maximize the effectiveness of ultrasonic cleaning. If you are looking to improve your industrial cleaning process with the best technology available, our experts can advise you on the best solution for your needs.

CONTACT US NOW

News

Difference between submersible ultrasonic transducers and plate ultrasonic transducers

10 February de 2025

Submersible Ultrasonic Transducers and Plate-Mounted Ultrasonic Transducers

In the ultrasonic cleaning industry, the choice of transducer type is a key factor that directly influences the effectiveness of the cleaning process, energy efficiency and system adaptability. There are two main configurations of ultrasonic transducers: submersible and plate-mounted. Each has particular characteristics that make them suitable for different applications. DCM Ultrasonic takes an in-depth look at their differences, advantages and disadvantages, providing a complete guide to selecting the most suitable option for each specific case.What is an ultrasonic transducer?

An ultrasonic transducer is a device that converts electrical energy into high-frequency mechanical vibrations using the piezoelectric effect. These vibrations generate ultrasound waves in the cleaning liquid, producing the cavitation necessary to remove dirt, oils, residues and contaminants from the surfaces of objects submerged in the tank.

Transducers can be installed in different ways depending on the needs of the cleaning process and the characteristics of the tank. The two most common options are submersible transducers and plate transducers.

Submersible Ultrasonic Transducers

Submersible transducers are sealed modules that are installed inside the cleaning tank, either on the bottom or on the side walls. They are designed to integrate with external ultrasound systems and can be added or removed without modifying the structure of the tank.Advantages of Submersible Transducers

1. Uniform distribution of ultrasonic waves

Thanks to their ability to be installed in different positions within the tank, submersible transducers allow for a better distribution of ultrasonic energy, minimizing dead zones and optimizing the cleaning process.

2. Flexibility and Scalability

Submersible transducers can be added or relocated depending on the needs of the cleaning process. This allows the tank configuration to be adapted without requiring costly structural modifications.

3. Ease of maintenance and replacement

Since they are not permanently fixed to the tank, their maintenance and replacement is much simpler. In the event of failure or wear, they can be replaced without affecting the integrity of the tank or interrupting the production process for long periods.

4. Longer service life

Since submersible transducers are designed with a hermetically sealed stainless steel housing, their service life tends to be longer compared to plate transducers, which are subject to greater wear from direct contact with cleaning fluids and the action of chemicals.

5. Suitable for large volume tanks

For industrial cleaning systems that require large capacity tanks, submersible transducers can be installed in multiple locations to ensure efficient distribution of ultrasonic energy.

DCM ULTRASONIC GENERATORS AND EMITTERS

Ultrasonic Plate Transducers

Plate transducers are integrated into the base or walls of the cleaning tank and are part of its structure. They are usually permanently installed and require a specific tank design for proper implementation.Disadvantages of Plate Transducers

1. Less flexibility

Once installed, plate transducers cannot be easily relocated. If a change in ultrasound distribution is required, structural modifications to the tank are required, which means additional costs and production downtime.

2. More complex maintenance

In the event of failure or deterioration, repairing or replacing a plate transducer can be expensive and complex, as it involves intervening directly in the tank. This can translate into extended downtime and higher maintenance costs.

3. Increased wear and reduced service life

Because they are in direct contact with cleaning fluid and chemicals, plate transducers can suffer greater wear over time. In addition, residue build-up and corrosion can affect their performance.

4. Less efficient wave distribution

The fixed location of plate transducers can result in zones of lower ultrasonic intensity within the tank, which can compromise the effectiveness of the cleaning process, especially in configurations with complexly shaped parts.

5. Limitations in demanding industrial applications

For applications requiring high ultrasonic intensity or deep, uniform cleaning, plate transducers may not be the most suitable choice due to their limitations in distributing ultrasonic energy.

Comparison

The choice between submersible and plate transducers depends on a number of factors such as the type of application, tank size, required flexibility, and available budget. However, generally speaking, submersible transducers offer greater advantages in terms of efficiency, maintenance, flexibility, and service life, making them the preferred choice for most industrial applications.

Plate transducers may be suitable in cases where the tank structure is specifically designed for this type of installation and a more economical solution is prioritized in the initial phase. However, it is important to consider maintenance costs and long-term performance limitations before making a decision.

At DCM Ultrasonic, we offer advanced ultrasonic solutions with high-quality submersible transducers, designed to optimize cleaning processes in various industries. Our focus on innovation and efficiency ensures reliable equipment, with cutting-edge technology to maximize the effectiveness of ultrasonic cleaning. If you are looking to improve your industrial cleaning process with the best technology available, our experts can advise you on the best solution for your needs.

CONTACT US NOW