Thu, 17 Apr 2025 15:40:51 +0200

In this context, ultrasonic cleaning is positioned as a highly effective technology, capable of overcoming the limitations of conventional methods and adding value to operations in ports, workshops, and shipyards. Thanks to its ability to deeply remove contaminants, even on complex geometries and sensitive surfaces, ultrasound is becoming a standard in naval maintenance tasks.

The consequences of improper cleaning can include:

Conventional cleaning methods such as manual brushing, pressurized water blasting, or the use of chemical solvents have multiple limitations: High water and toxic product consumption, the need for laborious part disassembly, inability to access internal areas or complex geometries, possible abrasion damage to delicate components, or the generation of hazardous waste that is difficult to manage.

Can we help you with the maintenance of naval parts?

Ultrasonic cleaning is a technology based on the generation of high-frequency sound waves (20–80 kHz) in a liquid medium, usually water with a specialized detergent. These waves cause the physical phenomenon of cavitation, generating millions of microbubbles that violently collapse near surfaces, loosening dirt without damaging the base material.

The application of ultrasonic technology has marked a turning point in multiple industrial sectors thanks to its high performance. Its ability to deliver exceptional results in a wide variety of applications makes it an essential tool, especially in the cleaning of naval components and in facilities dedicated to power generation.

This technology allows for the effective treatment of elements such as pistons, injectors, turbochargers, large cylinder heads, and other large mechanical components. When it comes to servicing marine engines and boats, having advanced ultrasonic cleaning systems guarantees superior results. Its ease of integration and low resource requirements make it compatible with demanding industrial environments, both in automated cleaning lines and multi-stage configurations. Furthermore, these devices are designed with high resistance and a high load capacity, making them robust and reliable tools.

The cleaning process is based on cavitation, a reaction caused by the implosion of microbubbles in a liquid solution. This action completely removes contaminants adhering to the surfaces of submerged parts without compromising their integrity. As a result, not only is the process efficiency improved, but the quality of the final finish is also significantly increased.

Among the most notable benefits of this technology are the ability to achieve a thorough cleaning, even in hard-to-reach areas, and the complete elimination of waste, which is key from an environmental perspective. Furthermore, the automation of the process contributes to significantly reducing labor costs. Unlike traditional methods, which rely on operators or spray systems, ultrasonic cleaning offers a uniformity that is difficult to achieve through other means.

DISCOVER OUR INDUSTRIAL MACHINES FOR NAVAL MAINTENANCE

Cleaning Heat Exchangers and Cooling Systems

Heat exchangers, both in cooling and air conditioning systems on board, accumulate salts, algae, sludge, and oxides. These deposits reduce heat transfer and can lead to failure. Ultrasonic cleaning allows you to clean: Fins and internal tubes without complete disassembly and Limescale deposits without damaging the material.

Marine Diesel Engines: Cylinder Heads, Blocks, Injectors, and Valves

In marine engines, parts accumulate carbon deposits, burnt oil, oxides, and metal residues. Ultrasonic cleaning machines effectively clean: Cylinder heads and engine blocks, Injectors, Valves, pistons, and crankshafts.

Hydraulic and Pneumatic Components

Pumps, control valves, accumulators, and hydraulic cylinders require thorough cleaning to maintain precision and prevent internal contamination. Ultrasound removes: metal sludge, lubricant residue, and abrasive particles.

Structural and Deck Components

Metal parts, hardware, pulleys, shackles, bearings, tools, and deck components benefit from a uniform cleaning that removes rust, grease, and dirt without the need for mechanical abrasion.

At DCM Ultrasonic, we understand the importance of offering solutions that not only solve immediate needs but also provide long-term value. Therefore, in addition to providing ultrasonic cleaning equipment, we actively advise on its application in the comprehensive maintenance of vessels and their critical components. The use of ultrasound in marine maintenance has gained ground due to its excellent results: it allows for deep cleaning in less time, reduces operating costs, and minimizes environmental impact.

If you're looking for a modern and responsible method to keep your boat in top condition, ultrasonic cleaning is an ideal option. It not only precisely removes dirt and debris, but also helps preserve materials and improve operational efficiency, especially in processes such as technical degreasing of naval components.

We are happy to provide more details on how to integrate this technology into your maintenance routines. Don't hesitate to contact us; our team will be happy to help.

News

Naval Maintenance with Ultrasonics

17 April de 2025

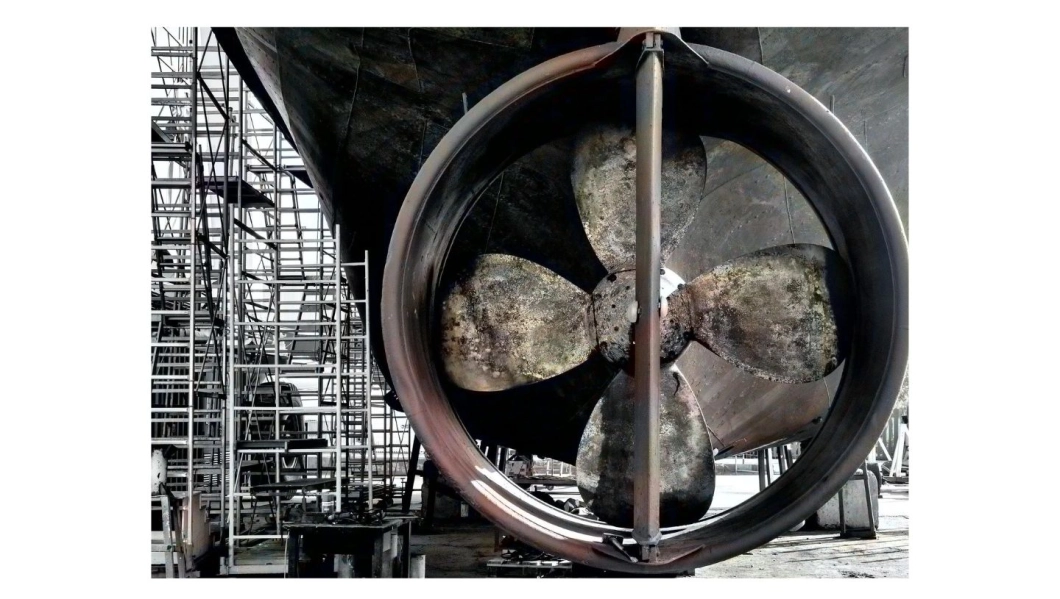

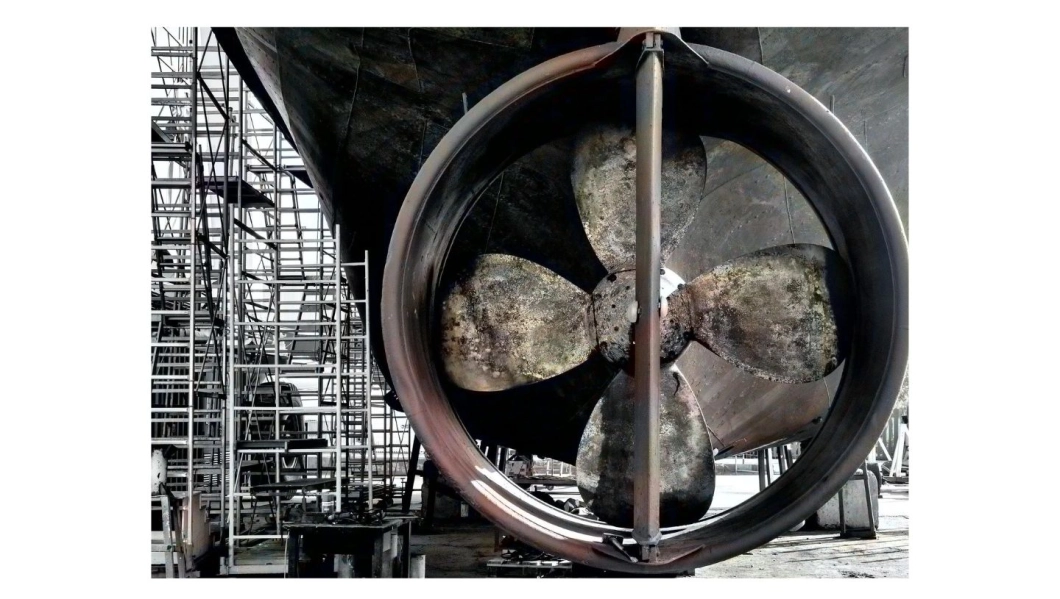

The naval industry, both civil and military, requires demanding maintenance processes to ensure the performance, safety, and durability of its components and systems. Continuous exposure to saline environments, humidity, contamination, and mechanical stress makes the cleaning of parts, equipment, and installations a fundamental pillar of preventive and corrective maintenance.In this context, ultrasonic cleaning is positioned as a highly effective technology, capable of overcoming the limitations of conventional methods and adding value to operations in ports, workshops, and shipyards. Thanks to its ability to deeply remove contaminants, even on complex geometries and sensitive surfaces, ultrasound is becoming a standard in naval maintenance tasks.

The Challenge of Maintenance in the Maritime Environment

Vessels and maritime structures operate in one of the most aggressive environments on the planet. The salinity of the water, the presence of algae and microorganisms, heat, pressure, and industrial contaminants accelerate corrosion, scaling, and deterioration of mechanical, hydraulic, and electronic systems.The consequences of improper cleaning can include:

- Cooling system failures due to clogged heat exchangers.

- Loss of efficiency in engines and turbines.

- Electrical failures due to accumulated dirt on panels and connectors.

- Accelerated wear of hydraulic and pneumatic components.

- Increased fuel consumption and emissions.

Conventional cleaning methods such as manual brushing, pressurized water blasting, or the use of chemical solvents have multiple limitations: High water and toxic product consumption, the need for laborious part disassembly, inability to access internal areas or complex geometries, possible abrasion damage to delicate components, or the generation of hazardous waste that is difficult to manage.

Can we help you with the maintenance of naval parts?

Ultrasonic cleaning for naval maintenance

Ultrasonic cleaning is a technology based on the generation of high-frequency sound waves (20–80 kHz) in a liquid medium, usually water with a specialized detergent. These waves cause the physical phenomenon of cavitation, generating millions of microbubbles that violently collapse near surfaces, loosening dirt without damaging the base material.The application of ultrasonic technology has marked a turning point in multiple industrial sectors thanks to its high performance. Its ability to deliver exceptional results in a wide variety of applications makes it an essential tool, especially in the cleaning of naval components and in facilities dedicated to power generation.

This technology allows for the effective treatment of elements such as pistons, injectors, turbochargers, large cylinder heads, and other large mechanical components. When it comes to servicing marine engines and boats, having advanced ultrasonic cleaning systems guarantees superior results. Its ease of integration and low resource requirements make it compatible with demanding industrial environments, both in automated cleaning lines and multi-stage configurations. Furthermore, these devices are designed with high resistance and a high load capacity, making them robust and reliable tools.

The cleaning process is based on cavitation, a reaction caused by the implosion of microbubbles in a liquid solution. This action completely removes contaminants adhering to the surfaces of submerged parts without compromising their integrity. As a result, not only is the process efficiency improved, but the quality of the final finish is also significantly increased.

Among the most notable benefits of this technology are the ability to achieve a thorough cleaning, even in hard-to-reach areas, and the complete elimination of waste, which is key from an environmental perspective. Furthermore, the automation of the process contributes to significantly reducing labor costs. Unlike traditional methods, which rely on operators or spray systems, ultrasonic cleaning offers a uniformity that is difficult to achieve through other means.

DISCOVER OUR INDUSTRIAL MACHINES FOR NAVAL MAINTENANCE

Applications of Ultrasonic Cleaning in Naval Maintenance

Cleaning Heat Exchangers and Cooling Systems

Heat exchangers, both in cooling and air conditioning systems on board, accumulate salts, algae, sludge, and oxides. These deposits reduce heat transfer and can lead to failure. Ultrasonic cleaning allows you to clean: Fins and internal tubes without complete disassembly and Limescale deposits without damaging the material.

Marine Diesel Engines: Cylinder Heads, Blocks, Injectors, and Valves

In marine engines, parts accumulate carbon deposits, burnt oil, oxides, and metal residues. Ultrasonic cleaning machines effectively clean: Cylinder heads and engine blocks, Injectors, Valves, pistons, and crankshafts.

Hydraulic and Pneumatic Components

Pumps, control valves, accumulators, and hydraulic cylinders require thorough cleaning to maintain precision and prevent internal contamination. Ultrasound removes: metal sludge, lubricant residue, and abrasive particles.

Structural and Deck Components

Metal parts, hardware, pulleys, shackles, bearings, tools, and deck components benefit from a uniform cleaning that removes rust, grease, and dirt without the need for mechanical abrasion.

At DCM Ultrasonic, we understand the importance of offering solutions that not only solve immediate needs but also provide long-term value. Therefore, in addition to providing ultrasonic cleaning equipment, we actively advise on its application in the comprehensive maintenance of vessels and their critical components. The use of ultrasound in marine maintenance has gained ground due to its excellent results: it allows for deep cleaning in less time, reduces operating costs, and minimizes environmental impact.

If you're looking for a modern and responsible method to keep your boat in top condition, ultrasonic cleaning is an ideal option. It not only precisely removes dirt and debris, but also helps preserve materials and improve operational efficiency, especially in processes such as technical degreasing of naval components.

We are happy to provide more details on how to integrate this technology into your maintenance routines. Don't hesitate to contact us; our team will be happy to help.