Thu, 24 Apr 2025 09:57:38 +0200

Its main objective is to maintain the quality of the final product, prevent breakdowns, extend the life of equipment, ensure worker safety, and comply with health and safety regulations. Among the various cleaning methods and techniques, at DCM Ultrasonic we specialize in offering ultrasonic cleaning solutions.

DISCOVER MORE ABOUT OUR INDUSTRIAL CLEANING SOLUTION

Industrial cleaning is a cross-cutting need in numerous sectors, including:

There are several cleaning methods in industrial environments, each with its own benefits and limitations, depending on the type of part, the level of dirt present, the production volume, and the level of cleaning required.

Manual Cleaning

This method relies on the operator's physical labor using basic tools such as brushes, spatulas, rags, or solvents. Although it can be effective for spot cleaning or cleaning easily accessible surfaces, it is inefficient in terms of time and effort when dealing with parts with complex geometries or large volumes. Furthermore, the constant use of chemicals can pose risks to both the worker and the environment.

Water or Sandblasting

This procedure is primarily used to remove rust, paint, or adhering dirt through the impact of pressurized water or abrasive particles (such as sand, microbeads, or bicarbonate). While fast and effective on external surfaces, it can damage delicate materials or electronic components. It also generates solid waste and dust that must be properly managed, in addition to requiring specialized personal protective equipment.

Chemical Cleaning

This involves the use of acidic, alkaline, or specific solvent solutions to dissolve contaminants. It is effective for treating grease, oil, carbon, and oxides, but its main disadvantage lies in the handling and subsequent management of chemical waste, which can be hazardous and require very strict safety and neutralization protocols. Furthermore, prolonged exposure of parts to these products can cause corrosion or wear.

CIP/SIP Systems (Clean In Place / Sterilize In Place)

These technologies are specifically designed for closed installations such as tanks, piping circuits, or heat exchangers. They allow cleaning and sterilization without disassembling the equipment, saving time and reducing the risk of contamination. They are widely used in the food, pharmaceutical, and cosmetics industries. However, they require a considerable initial investment and proper automation to operate efficiently.

Thermal or Cryogenic Cleaning

Thermal cleaning uses steam or intense heat to soften and remove contaminants, while cryogenic cleaning uses solid carbon dioxide (dry ice) to rapidly shrink and loosen dirt. These methods are effective for heavy-duty maintenance tasks, but are limited when working with small or intricate parts. Furthermore, both require precise control of process conditions to avoid material damage.

Ultrasonic Cleaning

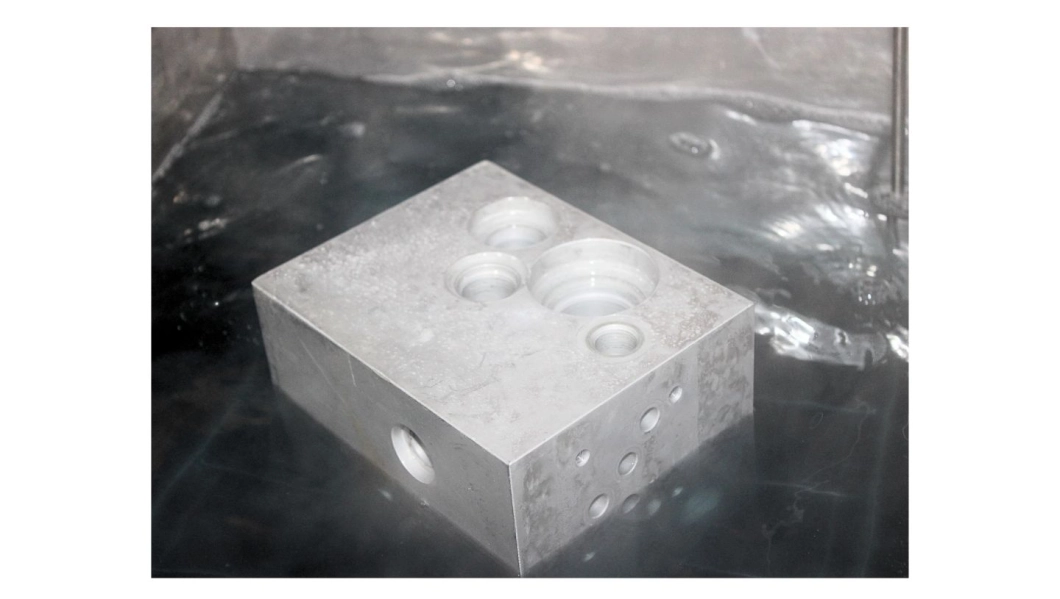

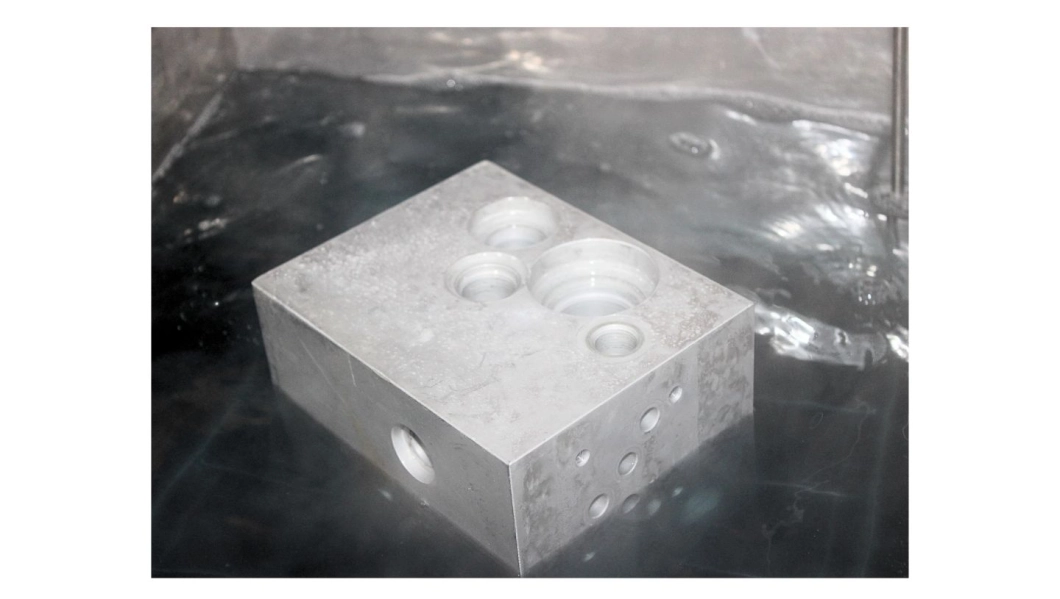

Ultrasonic cleaning is an advanced technology that stands out for its efficiency, precision, and environmental friendliness. It uses high-frequency sound waves that, when passed through a detergent liquid, generate microbubbles that forcefully collapse onto the surfaces to be cleaned. This phenomenon, known as cavitation, allows access to microscopic corners and interiors without the need to disassemble parts or apply harsh products.

CAN WE HELP YOU FIND THE CLEANING SOLUTION YOU NEED?

Ultrasonic cleaning has emerged as one of the most effective and technologically advanced solutions in the industrial field. It uses high-frequency sound waves (generally between 20 kHz and 100 kHz) that, when transmitted through a cleaning liquid, generate a physical phenomenon called cavitation.

This phenomenon produces millions of microbubbles that collapse forcefully onto the part's surface, removing contaminant particles without the need for abrasion or aggressive products. It is ideal for parts with complex geometries, internal cavities, small holes, or delicate surfaces.

At DCM Ultrasonic, we specialize in ultrasonic cleaning technologies. We manufacture high-performance industrial machines adapted to a wide variety of sectors and applications. Our product range is designed to provide precision cleaning, energy savings, and environmental sustainability.

Industrial cleaning is not just about keeping facilities or equipment clean. It is a key strategy for maximizing operational efficiency, ensuring safety, and extending the lifespan of industrial assets. And among emerging technologies, ultrasonic cleaning is positioned as one of the most promising.

At DCM Ultrasonic, we work to ensure companies can benefit from efficient, sustainable, automated cleaning equipment tailored to their needs. Whether for simple applications or complex processes, our solutions are designed to deliver performance, reliability, and resource savings.

Are you looking to improve your industrial cleaning system?

Contact us and discover how DCM Ultrasonic's ultrasonic technology can transform your cleaning process, increase productivity, and reduce your environmental impact.

News

What is industrial cleaning?

24 April de 2025

In the world of modern industry, where precision, safety, and efficiency are determining factors for the success of any operation, industrial cleaning has ceased to be a secondary task and has become a strategic pillar.What is industrial cleaning?

Industrial cleaning refers to the set of processes aimed at removing dirt, residues, contaminants, and other unwanted materials from surfaces, equipment, mechanical parts, or facilities within an industrial environment. Unlike domestic or commercial cleaning, industry handles much more complex materials and contaminants, such as oils, grease, metal particles, oxides, carbon, paint, and chemical or biological residues.Its main objective is to maintain the quality of the final product, prevent breakdowns, extend the life of equipment, ensure worker safety, and comply with health and safety regulations. Among the various cleaning methods and techniques, at DCM Ultrasonic we specialize in offering ultrasonic cleaning solutions.

DISCOVER MORE ABOUT OUR INDUSTRIAL CLEANING SOLUTION

Where is industrial cleaning applied?

Industrial cleaning is a cross-cutting need in numerous sectors, including:

- Automotive Industry: cleaning of engine components, cylinder heads, injectors, and gearboxes.

- Aeronautical Industry: maintenance of metal parts and hydraulic systems.

- Food Industry: sanitation of pipes, tanks, and heat exchangers.

- Pharmaceutical Industry: validated cleaning of vessels, CIP systems, and production components.

- Metallurgy and Machining: cleaning of swarf, oils, coolants, and oxides.

- Electronics Sector: cleaning of printed circuit boards and microcomponents.

Common Industrial Cleaning Methods

There are several cleaning methods in industrial environments, each with its own benefits and limitations, depending on the type of part, the level of dirt present, the production volume, and the level of cleaning required.Manual Cleaning

This method relies on the operator's physical labor using basic tools such as brushes, spatulas, rags, or solvents. Although it can be effective for spot cleaning or cleaning easily accessible surfaces, it is inefficient in terms of time and effort when dealing with parts with complex geometries or large volumes. Furthermore, the constant use of chemicals can pose risks to both the worker and the environment.

Water or Sandblasting

This procedure is primarily used to remove rust, paint, or adhering dirt through the impact of pressurized water or abrasive particles (such as sand, microbeads, or bicarbonate). While fast and effective on external surfaces, it can damage delicate materials or electronic components. It also generates solid waste and dust that must be properly managed, in addition to requiring specialized personal protective equipment.

Chemical Cleaning

This involves the use of acidic, alkaline, or specific solvent solutions to dissolve contaminants. It is effective for treating grease, oil, carbon, and oxides, but its main disadvantage lies in the handling and subsequent management of chemical waste, which can be hazardous and require very strict safety and neutralization protocols. Furthermore, prolonged exposure of parts to these products can cause corrosion or wear.

CIP/SIP Systems (Clean In Place / Sterilize In Place)

These technologies are specifically designed for closed installations such as tanks, piping circuits, or heat exchangers. They allow cleaning and sterilization without disassembling the equipment, saving time and reducing the risk of contamination. They are widely used in the food, pharmaceutical, and cosmetics industries. However, they require a considerable initial investment and proper automation to operate efficiently.

Thermal or Cryogenic Cleaning

Thermal cleaning uses steam or intense heat to soften and remove contaminants, while cryogenic cleaning uses solid carbon dioxide (dry ice) to rapidly shrink and loosen dirt. These methods are effective for heavy-duty maintenance tasks, but are limited when working with small or intricate parts. Furthermore, both require precise control of process conditions to avoid material damage.

Ultrasonic Cleaning

Ultrasonic cleaning is an advanced technology that stands out for its efficiency, precision, and environmental friendliness. It uses high-frequency sound waves that, when passed through a detergent liquid, generate microbubbles that forcefully collapse onto the surfaces to be cleaned. This phenomenon, known as cavitation, allows access to microscopic corners and interiors without the need to disassemble parts or apply harsh products.

CAN WE HELP YOU FIND THE CLEANING SOLUTION YOU NEED?

Industrial Ultrasonic Cleaning: A Revolution in the Sector

Ultrasonic cleaning has emerged as one of the most effective and technologically advanced solutions in the industrial field. It uses high-frequency sound waves (generally between 20 kHz and 100 kHz) that, when transmitted through a cleaning liquid, generate a physical phenomenon called cavitation.This phenomenon produces millions of microbubbles that collapse forcefully onto the part's surface, removing contaminant particles without the need for abrasion or aggressive products. It is ideal for parts with complex geometries, internal cavities, small holes, or delicate surfaces.

Key Advantages of Industrial Ultrasonic Cleaning

- Extreme efficiency: removes oils, greases, oxides, and microparticles evenly.

- Part care: does not damage delicate surfaces or electronic components.

- Deep cleaning: even in hard-to-reach areas that other methods cannot reach.

- Process speed: reduces cleaning times compared to manual methods.

- Sustainability: reduced use of chemicals and water.

- Automatable: can be integrated into production or maintenance lines.

DCM Ultrasonic: Innovation and Sustainability in Ultrasonic Cleaning

At DCM Ultrasonic, we specialize in ultrasonic cleaning technologies. We manufacture high-performance industrial machines adapted to a wide variety of sectors and applications. Our product range is designed to provide precision cleaning, energy savings, and environmental sustainability.Industrial cleaning is not just about keeping facilities or equipment clean. It is a key strategy for maximizing operational efficiency, ensuring safety, and extending the lifespan of industrial assets. And among emerging technologies, ultrasonic cleaning is positioned as one of the most promising.

At DCM Ultrasonic, we work to ensure companies can benefit from efficient, sustainable, automated cleaning equipment tailored to their needs. Whether for simple applications or complex processes, our solutions are designed to deliver performance, reliability, and resource savings.

Are you looking to improve your industrial cleaning system?

Contact us and discover how DCM Ultrasonic's ultrasonic technology can transform your cleaning process, increase productivity, and reduce your environmental impact.